For more than eight decades, FIUKA has represented the highest level of expertise in cold forming, deep-drawing and component manufacturing.

What began in 1938 as a family business is now an internationally positioned system partner with locations in Germany and Poland –

and a reliable partner for companies across a wide range of industries.

With state-of-the-art manufacturing processes, a clear focus on sustainability and a team of experienced specialists, we create products that set benchmarks – from the initial idea to full-scale series production. Benefit from a partner who combines technological strength, responsible action and efficient processes to move your projects safely into the future.

Our performance range extends from the first idea and prototype development to large-scale serial production. We combine decades of experience with cutting-edge manufacturing technology: presses up to 1,600 tons, high-speed lamination for electric motors, flow-forming processes for complex geometries and fully automated welding and assembly systems. This is how we create components used wherever precision, safety and efficiency are essential.

FIUKA – not only for the mobility of the future

Our technologies are also applied in mechanical and plant engineering, electrical engineering, the energy sector and infrastructure projects.

Wherever metal must be formed, moved and made resilient, we develop tailor-made solutions.

Our standards remain the same: highest quality, absolute reliability and genuine partnership. We see ourselves not just as a manufacturer, but as a development partner – making ideas possible, optimising costs and transferring processes safely into series production.

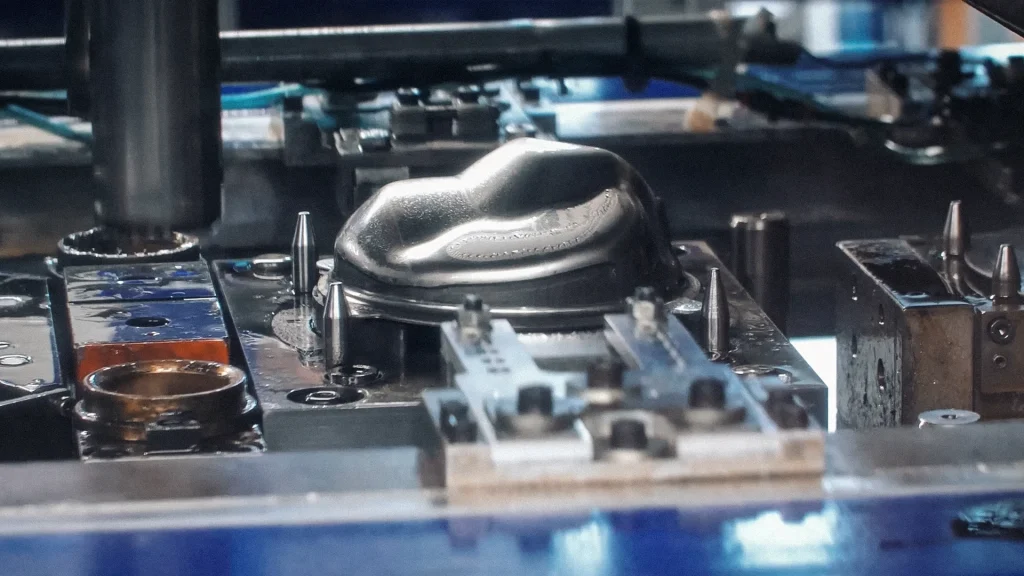

Deep-drawing technology enables the production of parts with simple to highly complex geometries.

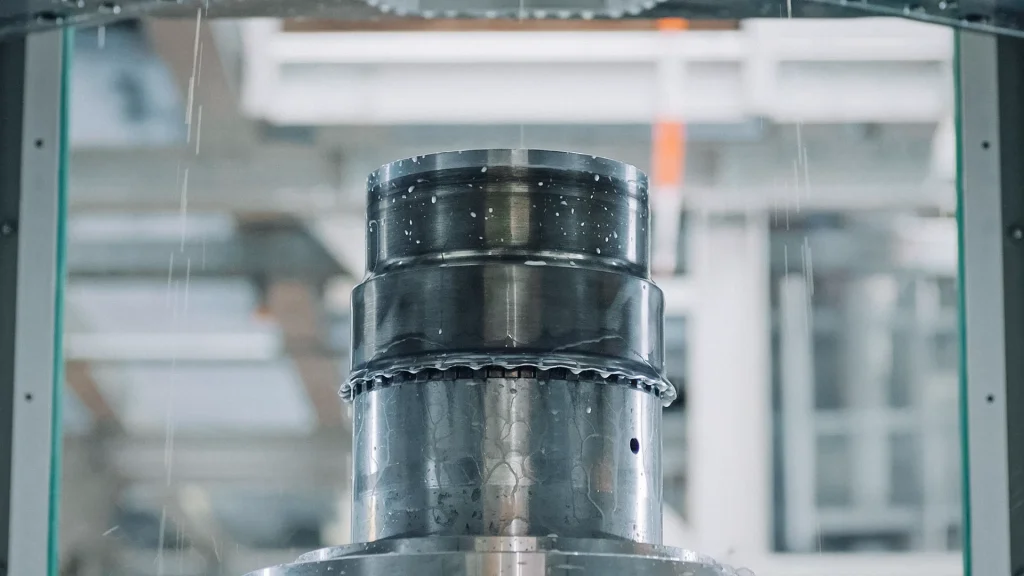

With press forces up to 1,600 tons, components are produced that impress through tight tolerances, stable processes and cost-efficient series production.

Our spinning technology enables the efficient production of rotationally symmetrical components.

Modern equipment ensures constant wall thicknesses, excellent surface finishes and precise concentricity – ideal for drive and transmission components.

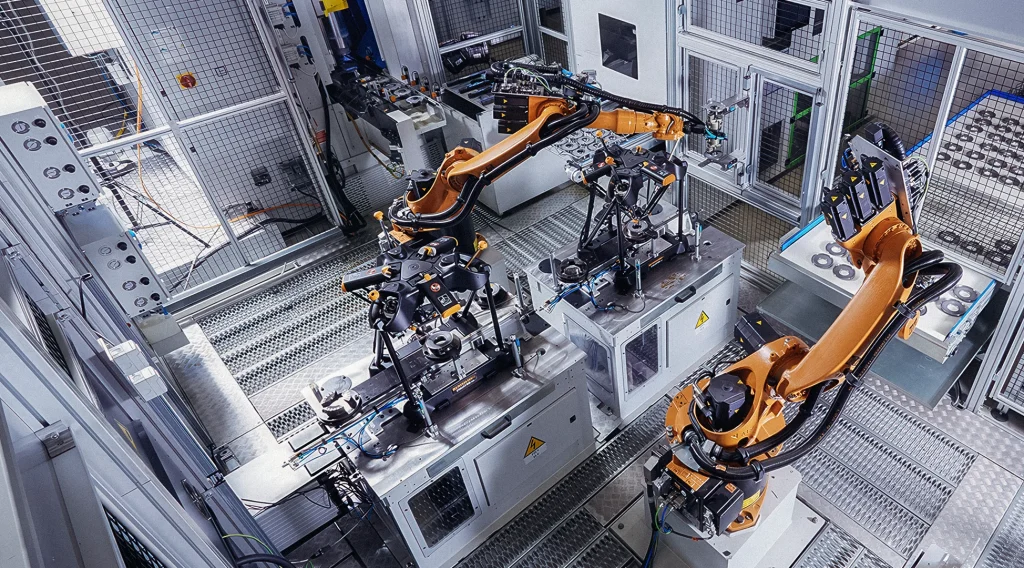

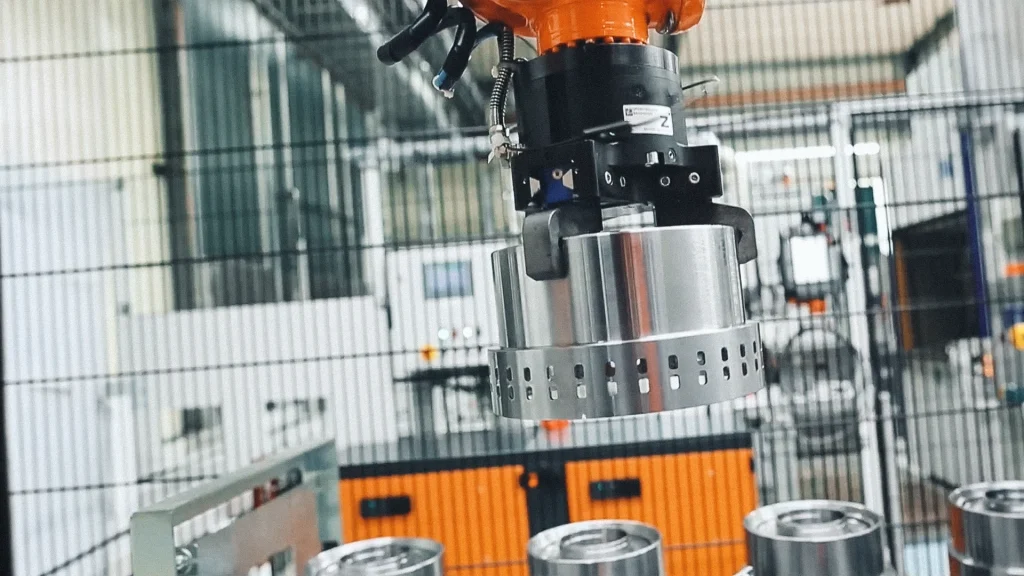

FIUKA supplies complete assemblies from a single source. Welding, joining and assembling are carried out on modern production lines.

MIG/MAG, TIG, CMT and resistance welding ensure durable, load-bearing connections – precisely executed and process-reliable in series.

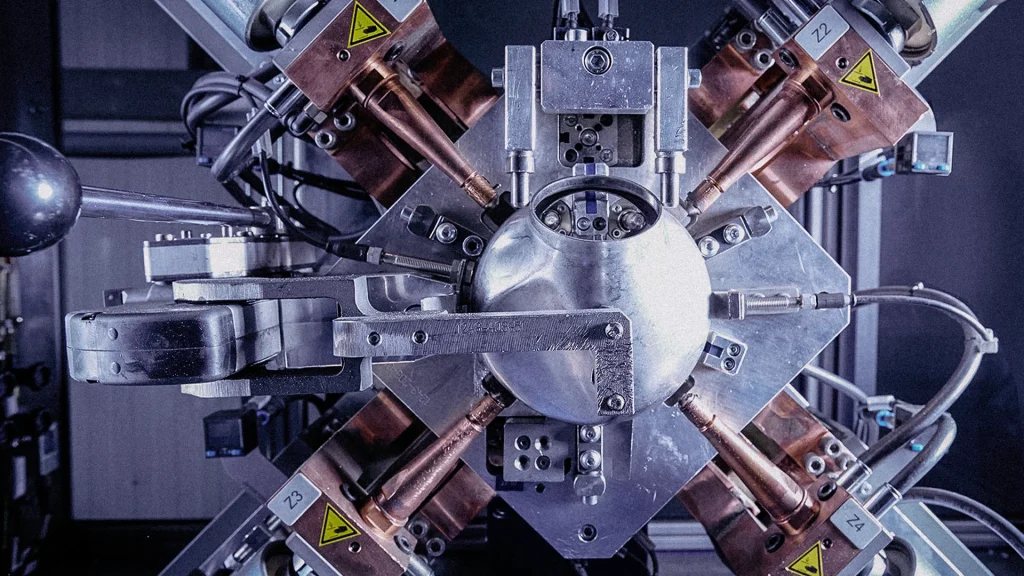

FIUKA manufactures precision electrical steel laminations and processes them into rotor and stator stacks for modern electric motors.

High-speed lamination guarantees tight tolerances, clean cut edges and uniform stack heights – crucial for minimal losses and high motor performance.

Progressive and transfer tools ensure clean cut edges with short cycle times.

Defined bending angles and controlled springback guarantee accurate contours – from prototype to large-scale series.

We help our customers rethink existing designs.

By replacing complex cast parts with forming technology, we create cost-effective alternatives with equal functionality.

Where multiple components come together, we develop solutions that merge them into one part – with fewer production steps, lower costs and higher process reliability in series.

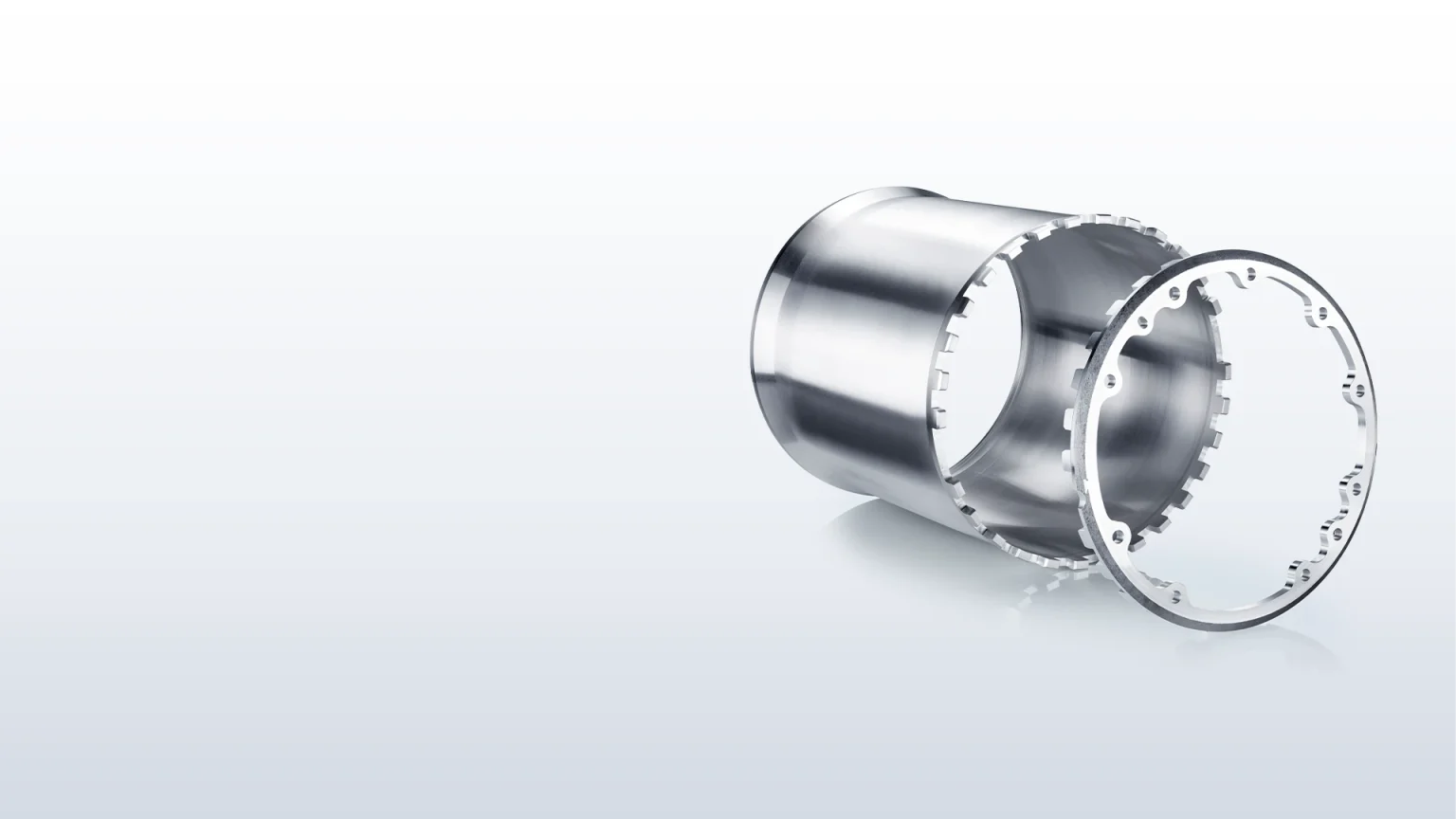

Flow forming enables the production of rotationally symmetrical parts with variable wall thicknesses and complex contours.

The process offers optimal material utilisation, reduced weight and high component strength – ideal for precise serial manufacturing.

In addition to forming technology, we machine parts and assemblies, from samples to series production.

Turning, milling, drilling, broaching, reaming and thread moulding ensure fits, axial run-out and coaxiality where it counts. Customer requirements are checked during the process and results are documented.

In component production, machined parts flow directly into welding and assembly – ready for your production line.

FIUKA offers near-series prototype manufacturing for all technologies used.

This allows customers to test and validate their developments on real components before series launch – enabling confident decisions and reliable process transfer.

for well-founded decisions and reliable process transfer.

We manufacture components for all types of vehicles – from airbag and chassis parts to powertrain, exhaust and e-mobility solutions.

Stable processes, documented testing and full traceability ensure serial quality and on-time delivery to your production line.

Components for drivetrain, chassis and hydraulics – designed to withstand shocks, dirt, fertilisers and heavy load cycles in demanding field conditions.

We manufacture deep-drawn housings, spun parts, flow-formed clutch bells, stamped-bent parts and welded assemblies – optionally with final machining for sealing and fitting surfaces.

Materials: high-strength steels and stainless steel..

Surface finishes: e.g. Zn-Ni, KTL or hot-dip galvanising.

The FIUKA UK-PV-FKG mounting system features a continuous click-system for fast, low-tool installation. UK-PV-FKG relies on a consistent click system for quick installation with few tools.

Few steps, a clear sequence, defined locking points – resulting in stable connections without unnecessary assembly effort.

Rooted in the automotive industry, we have continuously expanded our know-how and developed technologies that go far beyond classic vehicle applications. Today, our products are used wherever metal must be formed, moved and made durable.

In automotive and mobility, we manufacture safety- and function-critical components – from airbag systems to chassis and drivetrain parts, to exhaust and e-mobility solutions. Our precision and process reliability help make vehicles more efficient, safer and more sustainable.

Beyond that, companies from mechanical engineering, energy and electrical industries rely on our expertise. Whether robust parts for industrial applications or highly precise rotor and stator laminations for electric drives – we deliver solutions that meet the highest standards of dimensional accuracy, load capacity and cost efficiency.

We are more than an automotive supplier. We see ourselves as a cross-industry development partner combining modern forming technology and decades of experience to realise the right solution for every project.

We manufacture components for all types of vehicles – from airbag and chassis parts to powertrain, exhaust and e-mobility solutions.

Stable processes, documented testing and full traceability ensure serial quality and on-time delivery to your production line.

Components for drivetrain, chassis and hydraulics – designed to withstand shocks, dirt, fertilisers and heavy load cycles in demanding field conditions.

We manufacture deep-drawn housings, spun parts, flow-formed clutch bells, stamped-bent parts and welded assemblies – optionally with final machining for sealing and fitting surfaces.

Materials: high-strength steels and stainless steel..

Surface finishes: e.g. Zn-Ni, KTL or hot-dip galvanising.

The FIUKA UK-PV-FKG mounting system features a continuous click-system for fast, low-tool installation. UK-PV-FKG relies on a consistent click system for quick installation with few tools.

Few steps, a clear sequence, defined locking points – resulting in stable connections without unnecessary assembly effort.

From cold forming and deep drawing to roller forming and complex assemblies – we offer all processes from a single source.

Our components are used worldwide across industries – from automotive and e-mobility to powertrain and chassis technology, to exhaust and safety systems.

With high vertical integration, proven quality and an eye on future technologies, we contribute to durable and high-performance products.

Book your preferred date and talk to us about your project.